BE EFFICIENT

BE EFFICIENT by using your Rhodotron® to its fullest potential. The watchwords: highest throughput, biggest volume, maximum power. Get the most out of every kW that your Rhodotron® gives.

Together, let’s build a partnership that will last for life. When you come to us with your project, we accompany you from A to Z — till infinity.

Your BEYOND™ end-to-end solutions are designed according to your specific needs, to provide the most efficient irradiation center for your process and product.

100% E-beam 100% X-ray Dual modalities

Your Rhodotron® is the beating heart of your irradiation solution. This state-of-the-art, energy-efficient, stable and robust electron accelerator is the only one capable of such a wide power range – worldwide.

The best electrical engine for your irradiation solution.

From 20 kW to 560 kW

Your Rhodotron®’s modular design allows you to start with the power needed and increase the system’s capacity when required.

30% of energy savings

The Rhodotron® features a better use of energy when converting electricity to E-beam power. Compared with other high voltage accelerators, power consumption can be reduced by a factor three.

From 1 to 3 power amplifiers

Your Rhodotron®’s new modular design gives the option to have redundant and independent power amplifiers reducing downtime in the power chain to a minimum.

From 100 µA to 80 mA

The Rhodotron® is the only accelerator that can run with beam current ranging from a few microamps up to many milliamps. The energy remains very stable ensuring predictable dose deposition.

5 MEV – 7 MEV – 10 MEV – 40 MEV

Thanks to its unique features, the Rhodotron® can provide different beam energies, which enlarge the applications possibilities in E-beam and/or X-ray.

IBA provides support from the initial building design to ensure all the functional and safety requirements are met. We help you optimize the space around the system to improve the flow of products and simplify the work of the operators. We also help you optimize the footprint when space is scarce or when installing a new system in an existing building. IBA provides guidance and calculation notes for the irradiation vault shielding, the ozone extraction system, the building heat exchanger, the electrical input ratings, and more.

All solutions are powered by the Rhodotron® that will provide a stable electron beam, at the required energy, current and scan parameters. The versatility of our accelerators allows to deliver the type of irradiation, the power and the configuration you need without power wastage.

IBA provides a fully compliant radiation safety solution designed to ensure the safety of all working personnel on site. A safety PLC monitors the status of the system and prevents unwanted intrusion in high radiation areas when the system is on.

IBA provides, in collaboration with its partners, a complete dosimetry suite. Dosimetry can be used to validate the installation and to perform regular checks. It can be used to validate new products as well as routine dosimetry.

Based on a strong experience with the integration of irradiation systems, IBA has developed the Beagle® suite, a process control system designed to handle the recipe data, to control the loading and unloading process and to monitor the whole irradiation process.

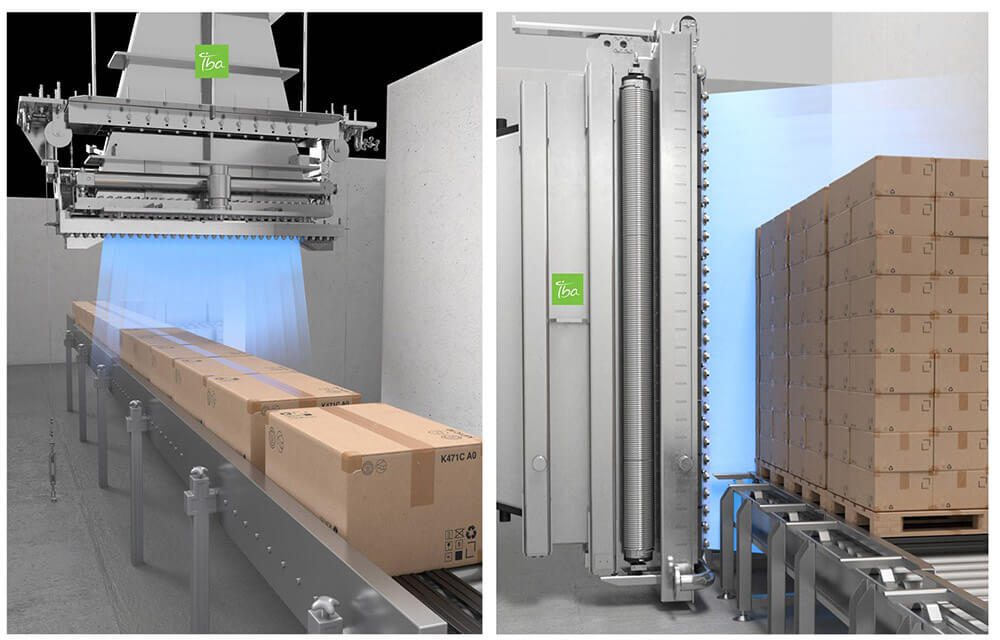

IBA works hand-in-hand with conveyor providers to be able to offer a full range of product handling systems. Boxes or trays, pallets or totes, single or double level, we will make the most suitable suggestion to match your production requirements.

Some degree of automation is essential to load and unload the system. Together with our partners, we offer a full range starting from palletizing and depalletizing robots, automated pallet stretch wrappers, to automated storage handling systems.

Once the Site Acceptance Tests (SAT) of the integrated solutions have been performed, IBA can provide support for IQ/OQ/PQ to help you make your center operational as fast as possible. After the official start, IBA proposes assistance by an expert to ramp-up your production and reach out for the full potential of your installation.

Together, let’s build a partnership that will last for life.

When you come to us with your project, we accompany you from A to Z — till infinity.

Your BEYOND™ end-to-end solutions are designed according to your specific needs, to provide the most efficient irradiation center for your process and product.

Depending on your product packaging, variety and sensitivity to manipulations, you can start your journey with us by choosing from four fundamental families that have been designed and optimized.

BE EFFICIENT by using your Rhodotron® to its fullest potential. The watchwords: highest throughput, biggest volume, maximum power. Get the most out of every kW that your Rhodotron® gives.

BE SOFT on your most delicate products. When flipping is not possible, your BE SOFT solution will delicately irradiate your products laterally and rotate them in the most thoughtful way.

BE WIDE and don’t be afraid to think big. Your BE WIDE solution is especially designed for pallets irradiation in X-ray. With an extremely extensive lateral horn, two pallets can be irradiated at the same time. High throughput and X-ray are the criteria.

BE FLEX with your solution for a multi-purpose irradiation center. Pallets or boxes, food treatment or medical device irradiation, E-beam or X-rays? No need to choose: you have 2 centers in one. Should you choose the BE FLEX solution, your project will be sustained by strong R&D support.

Be-In, your portal to information anytime, anywhere.

Operating in the cloud, keeps you informed about vital parameters of your equipment and proactively alerts you about potential risks, ensuring you’re never caught off guard.

It’s a dynamic community space where all users connect to the IBA INDUSTRIAL support organization. Be-In is about staying connected, informed, and inspired. Be-In is a comprehensive platform offering intuitive dashboarding, effective troubleshooting, proactive maintenance, and a wide range of intelligent insights. Supported by training materials, an integrated store and a ticketing tool for smooth operations, Be-In paves the way to operational excellence. Be-In creates an interactive community where insights are gained, and your success is our priority.

Experience unparalleled efficiency and precision with Beagle, revolutionizing your irradiation processes like never before.

Beagle is an integrated SCADA (Supervisory Control and Data Acquisition) software solution designed for the precise control of Electron Beam and X-ray irradiation processes. It features a robust Manufacturing Execution System (MES) for customizing irradiation recipes, a Process Control System (PCS) for real-time operational commands, and a Machine Control System (MCS) for continuous monitoring of process parameters. Beagle also offers seamless ERP integration for streamlined data communication and a specialized dosimetry connector for accurate dose measurements. With its comprehensive reporting tools, Beagle delivers detailed insights for each irradiated batch or product, ensuring quality and compliance in your irradiation projects.